Introduction of High Density Polyethylene Pipe (HDPE Pipe)

Compared with the traditional metal pipe and cement pipe, the polymer (plastic) pipe has the advantages of light weight, corrosion resistance, small water flow resistance, good comprehensive energy saving, convenient transportation and installation, long service life. Polymeric (plastic) pipe materials used are polyvinyl chloride (PVC), polyethylene (PE) and polypropylene. Compared with other plastic pipes (such as PVC), high-density polyethylene (HDPE) pipe with low density, good toughness, corrosion resistance, insulation performance, easy construction and installation.

HDPE pipe - the domestic building materials market, a new kind of pipe, the market is also commonly known as "black tube", "PE water pipe." At present, the new type of polymer (plastic) pipe is stable development, PE pipe, PP-R pipe, UPVC pipe has a place, in which PE pipe in the use of public works development of the most eye-catching. PE pipe used in a wide range of areas, including supply / drainage, power / communication tube, gas pipe, sewage pipe is the main purpose.

Polyvinyl chloride (PVC) in the heat, oxygen, light, the structure will change. Therefore, PVC processing must be added to the stabilizer. Because PVC additives used (such as stabilizer, plasticizer) in recent years by the criticism, coupled with its flexibility, chemical resistance is not ideal, HDPE tube so increasingly attention and popularity. A variety of electrical pipes, for / drainage pipes, sewage pipes, gas pipes and even large pumping pipes, culvert, high-rise water pipes are more and more common use HDPE pipe.

PE pipe material introduction - polyethylene

Polyethylene resin is made of monomer ethylene polymerization, due to polymerization, pressure and temperature due to polymerization conditions are different, can be obtained different density of resin, and thus high density polyethylene, medium density polyethylene and low density Polyethylene. In the processing of different types of PE pipe, according to their application conditions, the choice of different raw materials, while the extruder and mold requirements are different.

HDPE pipe (PE pipe) the main purpose

★Civil and public works applications:

Telecommunications (force) pipeline outside the care, telecommunications (force) pipeline within the pipe, telecommunications (force) and fiber pipeline lead pipe, urban rainstorm collection and drainage system, sewer sewage pipe, slopes and drainage pipes, retaining Wall drainage pipe, iron road and bridge drainage pipe, industrial road drainage pipe, bridge drainage pipe, bridge cable protection tube, tunnel drainage pipe, culvert, culverts.

★Construction Engineering Applications:

Building drainage system, roof drainage system, roof drainage system, pool drainage, building drainage system, air garden set drainage system, foundation water treatment, Yinjing drainage, water pipe facilities. Factory waste water discharge pipe.

★Leisure Engineering Applications:Various sports venues underground drainage system, gardening water supply system, park playground drainage facilities management, parking lot rainwater collection and discharge pipe.

★Agricultural Engineering Applications:

Farmland drainage pipe, crop irrigation system, storage and ventilation system, arable land consolidation drainage system, storage tank underground drainage drainage system, waterway system.

HDPE pipe (PE pipe) for special purposes

★Sanitary landfill rain, sewage and biogas collection

★A variety of anti-acid and alkali, corrosion-resistant needs of the pipeline

★Natural gas, gas delivery pipe

★Mine sewage collection and discharge

★Aquaculture management

★Ship management

.jpg)

Introduction of PE pipe performance

1. Good sealing performance

P E pipe with fused connection, hot melt butt, hot melt socket, welding and mechanical pipe connection. The interface is stronger than the pipe itself. Will not be broken due to soil movement or load.

2. Good flexibility

P E tube has a unique flexibility of its elongation at break of more than 500%. The bending radius can be as small as 20 to 25 times the diameter, and it is easy to move during bending and interpenetting at the same time by the dry welding joint axial load without leakage and disengagement, so at the time of laying and bending There is no need for an "anchor" that does not cost much.

3. Earthquakes and shocks

PE pipe in the heavy pressure directly through the pipeline, will not lead to pipe rupture in the course of the use of dry pipe foundation adaptability. In the tube base occurs uneven settlement and dislocation is also easy to damage. While the requirements of the tube is low, can greatly save costs. It was reported in the 1995 Kobe earthquake in Japan. PE gas pipes and water supply pipes are the only pipes that are not damaged.

4. Low temperature, frost resistance

PE pipe low temperature performance is far better than PVC-U and other water supply pipe and gas pipe, at very low ambient temperature does not occur embrittlement and brittle fracture.

5. Low friction coefficient

PE pipe has excellent fluid friction performance, in the delivery of mud, crude oil and other fluid medium, the flow rate is better than metal and concrete pipe, while the service life is 4 times the steel pipe.

6. Easy to transport

PE pipe of light weight, density is only 1/8 of the steel, in the transport process can be used in accordance with the needs of users in the way tube transport.

HDPE pipe and other materials diameter and specifications of the expression:

1, water, steel pipe (galvanized or non-galvanized), cast iron pipe and plastic pipe and other pipe, should be marked with nominal diameter "DN" (such as DN15, DN50);

2, (Such as De108 × 4, De159 × 4.5, etc.); for seamless steel pipe or non-ferrous metal pipe Metal pipe, should be marked "outside diameter × wall thickness." For example ф108 × 4, ф can be omitted.

3, reinforced concrete (or concrete) pipe, clay pipe, acid-resistant ceramic tube, cylinder tile and other pipe, pipe diameter should be expressed in diameter d (such as d230, d380, etc.);

4, HDPE pipe and other plastic pipe, pipe diameter should be expressed in accordance with product standards;

5, When the design is denoted by the nominal diameter DN, the diameter DN shall be the same as the corresponding product specification.

Meaning of De, DN, D, d, Φ:

In general, the diameter of the pipe can be divided into outside diameter, inside diameter, nominal diameter.

1, DN refers to the nominal diameter of the pipe, is the average diameter and diameter. DN value = De value of -0.5 * wall thickness. Note: This is neither an outside diameter nor an inside diameter.

(Such as DN15, DN50) shall be marked with a nominal diameter "DN" for pipes such as water and gas transportation pipes (galvanized steel pipes or galvanized steel pipes), cast iron pipes, steel-plastic composite pipes and polyvinyl chloride (PVC) pipes.

2, De mainly refers to the pipe diameter, PPR, PE pipe, polypropylene tube diameter, generally marked with De, are required to be marked as the outer diameter * wall thickness of the form, De25 × 3.

3, D generally refers to the pipe diameter.

4, d concrete pipe diameter. Reinforced concrete (or concrete) pipe, clay pipe, acid-resistant ceramic tube, cylinder tile pipe and other pipe, diameter should be expressed in diameter d (such as d230, d380, etc.)

5, Φ that the diameter of ordinary circles; can also represent the outer diameter of the pipe, but this time should be multiplied by the wall thickness. Such as: Φ25 × 3, said tube with outer diameter of 25mm and wall thickness of 3mm. For seamless steel pipe or non-ferrous metal pipe,

"Outer diameter × wall thickness". For example ф108 × 4, ф can be omitted. China, ISO and Japan part of the steel pipe wall thickness of the standard wall thickness of the series. The representation of such steel pipe specifications for the pipe diameter × wall thickness. Such as ф60.5 × 3.8.

6, DN for Nominal diameter means nominal diameter.

7, De for external diameter means outside diameter.

De, DN, d, ф each indicate the range

1, De - PPR, PE pipe, polypropylene tube outside diameter

2, DN - high density polyethylene (HDPE) pipe, cast iron pipe, steel-plastic composite pipe, galvanized steel pipe nominal diameter

3, d - nominal diameter of concrete pipe

4, ф - seamless steel pipe or non-ferrous metal pipe should be marked "outside diameter × wall thickness", such as: ф108 X 4

Note: nominal diameter, also known as the average diameter. In order to make the pipe, pipe connection size uniform, using DN that its nominal diameter (also known as nominal caliber , nominal diameter).

Because there are metric and imperial distinctions, there is the following call method.

1, to metric as a benchmark, called DN

2, to the British as a benchmark, said NB

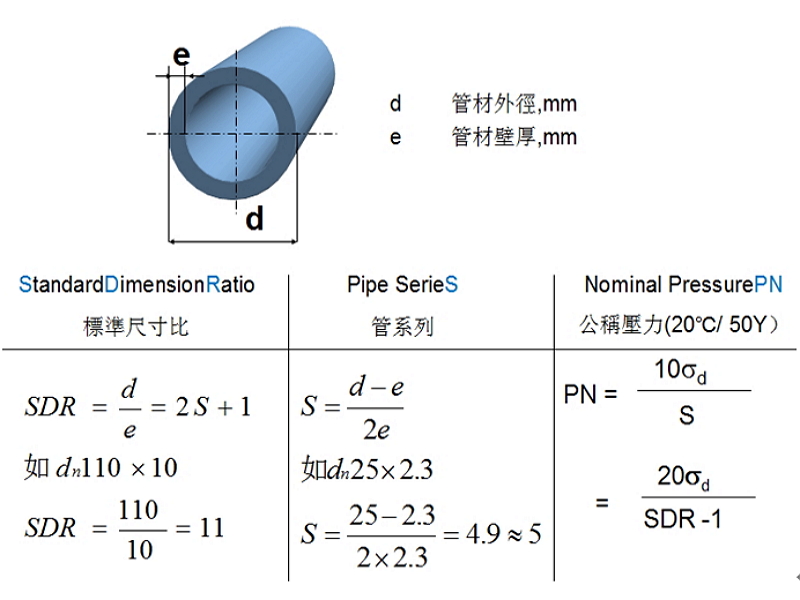

D =tube diameter(mm) S =wall thickness(mm)

SDR11 means that the outer diameter is 11 times the wall thickness

About Us

About Us